Additive Services

MK Machining is a small, quality-oriented business where we value our relationship with a customer over profit. We have the capabilities of larger service bureaus, but with a more personable and customer-focused mindset. Rather than simply trying to maximize machine output, we prefer to produce parts in a way that maximizes customers satisfaction. This means when preparing parts to be produced, we keep the customer’s requests at the forefront, whether this be mechanical quality or aesthetics. We set ourselves apart from larger service bureaus by offering design for additive manufacturing (DFAM) consulting services. Rapid advances in additive manufacturing have made part quantities, geometries, and materials that were not possible a few years ago now feasible.

our services

Rapid Prototyping

Have prototypes that you need rapidly turned around? We can help with as little as one business lead times.

production parts

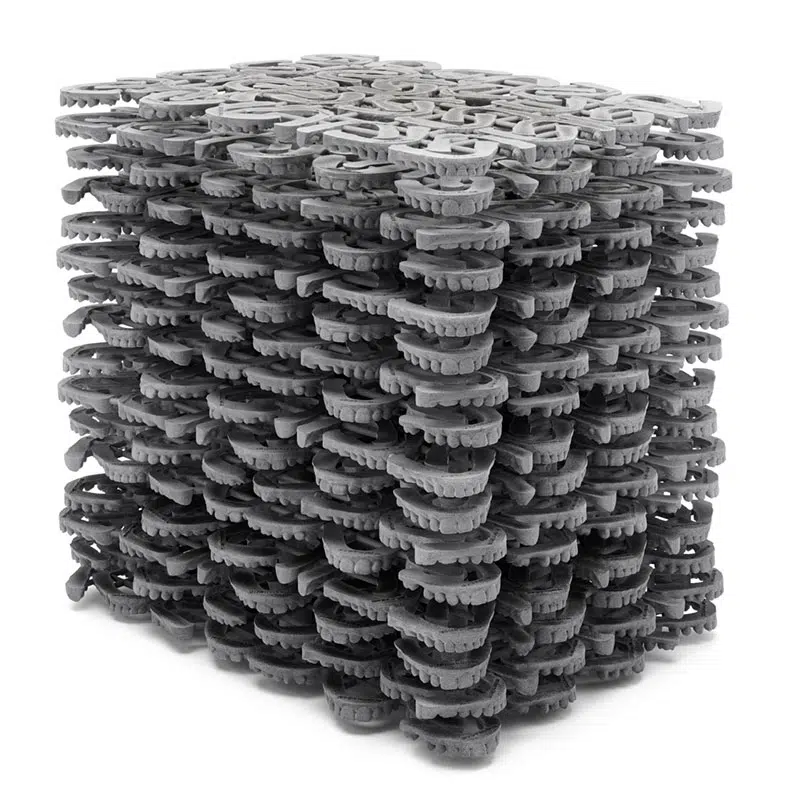

Whether a production batch is hundreds of parts or thousands of parts we can help. We pride ourselves on part consistency which means parts from the first batch will be the same as the last batch.

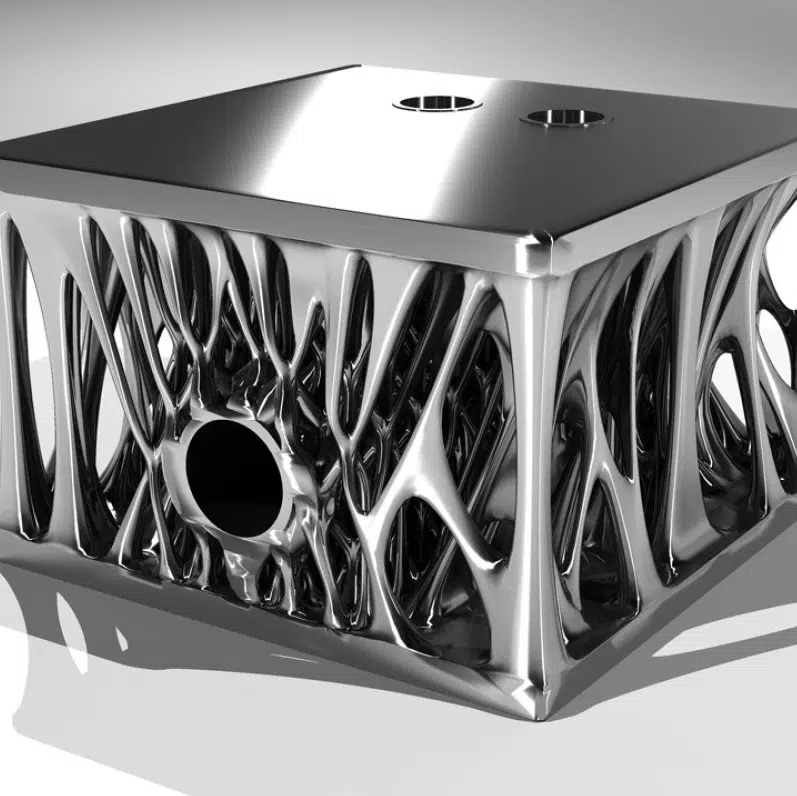

design for additive Manufacturing

Design for Additive Manufacturing allows us to assist customers with taking parts designed with traditional manufacturing in mind and refine them for additive manufacturing. This can result in parts that are significantly cheaper to produce with similar mechanical properties.

3D Scanning & Reverse Engineering

our expertise

Part quality

We produce parts in a manner that keeps the customer at the forefront. This means orienting customer parts for their desired outcomes, rather than for maximizing build volume. Parts produced in this way are of the upmost quality whether that be mechanical properties or aesthetics appearance.

consistency

We orient parts in the same way for every build which results in parts that are visually and mechanically consistent in build after build. This is especially useful in large production runs to ensure that parts from different batches look and function the same.

rapid turnaround

We are able to fulfill orders both large and small quickly. If you need prototypes made and shipped out within one business day we can help you. If you need a large batch of production parts completed on a short timeline we can help!

companies we've worked with